27 Sep, 2019

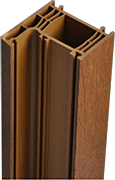

The Characteristics of Different Kinds of Film for Upvc Profiles |

First, the outer membrane PVDF window film

Advantages: good weather resistance, outdoor normal service life of more than 15 years; superior anti-aging and weather resistance; acid rain; surface can be wiped with solvent; surface has self-cleaning function, easy to clean; mask with PVDF with infrared permeability The alloy film (PVDF+PMMA) contains a reflective infrared pigment in the base film, which reduces the absorption of thermal energy by the film, reduces the temperature difference between the inside and outside of the substrate, and improves the stability of the substrate structure;

Disadvantages: the surface can not be bonded with other products; white powder may appear when the film is cut in winter; when it is coated with cold glue when the moisture is large in the southern rainy season, it is easy to produce when the solvent is not dried at all. bubble;

Advantages of different kinds of flim for upvc profiles |

Second:

(1) structure of the intimal PMMA surface (the advantages and disadvantages described below are compared with the inner membrane PVC structure)

Advantages: Weather resistance is better than PVC structure, indoor normal service life is 15 years; no film delamination occurs;

Disadvantages: the surface is not resistant to solvent wiping, wiping will destroy the structure of the surface, dissolve the color of the surface layer (solvent: organic solvent containing benzene, alcohol, ketone, ether, ester, alkane);

(2) Intima PVC double-layer composite structure

Advantages: the surface can be wiped with a less corrosive solvent;

Disadvantages: Weather resistance is worse than PMMA table, indoor normal service life is 8 years; long time storage in high temperature and high humidity environment will lead to decreased film peeling force (for example: in marine transportation in containers, medium and high humidity environment in Southeast Asia), film There will be stratification hidden dangers;

Note: The inner membrane has been changed from the original structure to the current PMMA surface structure, mainly to avoid the hidden danger of membrane delamination, because the environment of the exported product has many uncertain factors.