3 Aug, 2017

This post, we cover the process called extrusion, which is how uPVC windows and doors are born. At the beginning, the resin is mixed with *additives and **UV inhibitors before being gravity fed from a top mounted hopper into the barrel of the extruder. The material then encounters a rotating screw which forces the plastic beads forward and into the barrel which is heated to the desired melt temperature of the molten plastic (ranging from 200 to 275 degrees Celsius). This molten material then enters a the die. The die gives the profile its shape as it is being pulled through it.

The product is now cooled, which is done by pulling it through a water bath. Once sufficiently cooled, package labels and protective tape are adhered to the profiles, then cut into standard lengths for shipping and distribution. For the laminate profile, there is an additional step of the laminate film, which is the combination of the laminate film and the matrix profile. This is done with a special glue that is heat resistant and expansive, so the laminate will not peel.

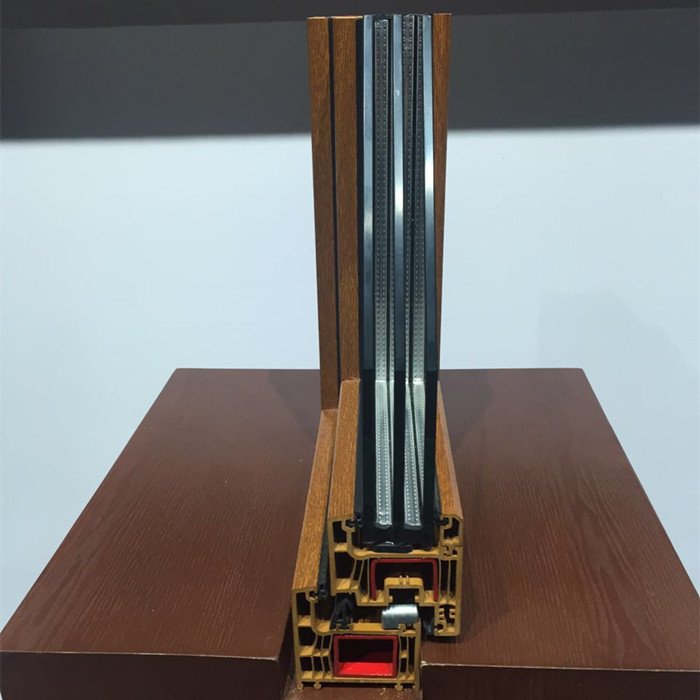

Through research and development, the optimal wall thickness and design of the product are achieved. If you’re wondering why there are chambers inside the outline, it’s because the number of chambers is crucial for doors and doors to have insulating properties.

Large plastic extruding companies such as Deceuninck, Kommerling, Veka, Rehau and others spend millions of dollars annually on R&D to improve the properties and design of their profiles.

It is worth noting that these additives are stabilizers for profiles. Common stabilizers include lead and calcium and zinc. Lead is toxic, but unfortunately many extrusion companies still use it. If your product is lead-free, check with your window manufacturer.

Titanium dioxide is also added to plastic steel profiles used in tropical countries, which have much higher UV exposure and can wear down the plastic steel profiles and cause discoloration. Again, not all manufacturers add titanium dioxide to resin mixtures because many of their profiles are temperate zone. Make an informed decision knowing that you are paying.

Thank you for reading this article and hope to give you some more ideas about the complex process of plastic steel extrusion and what to pay attention to. Remember, just like any other product, what little you see on the surface also reflects what goes on behind the scenes.